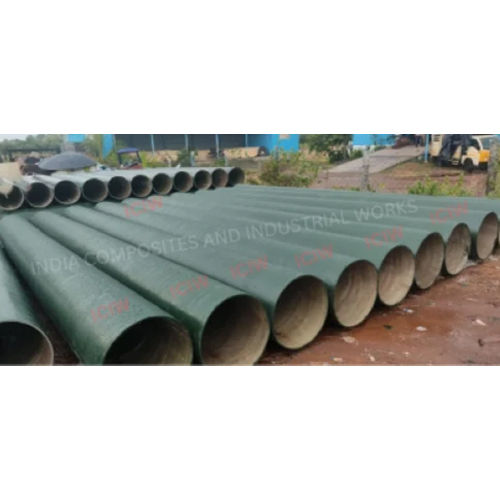

FRP/PP FRP Ducts

FRP/PP FRP Ducts Specification

- Usage & Applications

- Industrial

- Color

- Grey

- Size

- Standard

- Product Type

- FRP Ducts

- Usage

- Industrial

- Material

- FRP

FRP/PP FRP Ducts Trade Information

- Minimum Order Quantity

- 1 Square Meter

- Payment Terms

- Others

- Supply Ability

- 25 Square Meters Per Week

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About FRP/PP FRP Ducts

FRP PP FRP FRP stands for Fiber Reinforced Plastic. PP stands for Polypropylene, a type of thermoplastic polymer. FRP PP FRP typically refers to a sandwich structure or layered composite where: FRP layers (fiber-reinforced plastic) are used on the outer surfaces to provide strength, stiffness, and corrosion resistance. A PP (polypropylene) core is sandwiched between the FRP layers, offering lightweight properties, insulation, and sometimes flexibility. Applications: Used in panels, roofing sheets, or structural components where a combination of strength, lightweight, and chemical resistance is needed. Common in chemical plants, water treatment facilities, and construction. FRP Duct FRP Ducts are ducting systems made from Fiber Reinforced Plastic. These ducts are used to transport gases, air, or corrosive fumes in industrial environments. FRP ducts are lightweight, corrosion-resistant, and have excellent durability. They are preferred over metal ducts in environments where chemicals, moisture, or acids might cause corrosion or contamination. Features: Resistant to acid, alkali, and salt corrosion. Smooth internal surface reduces friction losses. Can be custom-shaped or fabricated to suit specific installations. Used in ventilation, exhaust systems, chemical processing plants, and HVAC systems.FAQs of FRP/PP FRP Ducts:

Q: What is the material used in FRP/PP FRP Ducts?

A: The material used in FRP/PP FRP Ducts is FRP (Fiber-Reinforced Plastic).Q: What is the standard color of FRP/PP FRP Ducts?

A: The standard color of FRP/PP FRP Ducts is Grey.Q: What is the usage of FRP/PP FRP Ducts?

A: FRP/PP FRP Ducts are primarily used for industrial applications.Q: Are the size specifications of FRP/PP FRP Ducts customizable?

A: FRP/PP FRP Ducts come in Standard size specifications.Q: What industry benefits the most from FRP/PP FRP Ducts?

A: Industries requiring durable and robust ducting systems benefit significantly from FRP/PP FRP Ducts.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FRP Products Category

FRP Motor Cover

Price 2500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : FRP

Color : ANY

Size : Standard

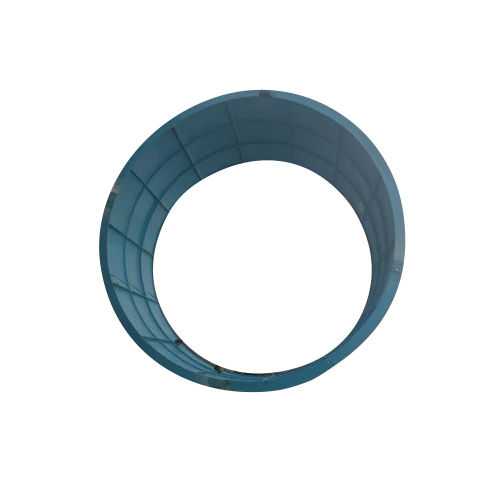

FRP And GRP Round Pipe

Price 1000 INR / Meter

Minimum Order Quantity : 10

Material : FRP & GRP`

Color : Grey

Size : Multiple

Usage : Industrial

FRP Retention Hood

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : FRP

Color : Blue

Size : Customized

Usage : Industrial

FRP Lining & Coating

Price 1500.0 INR / Square Meter

Minimum Order Quantity : 1 Square Meter

Material : MS

Color : Green

Size : Standard

Usage : Industrial

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free